Flowdirect UK Ltd's philosophy is one of ultra-reliability and outstanding service.

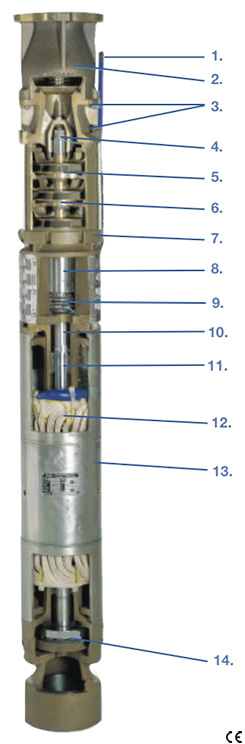

Using our 100 years of pumping experience and the latest computational techniques, the team at Flowdirect UK Ltd have engineered a submersible pump-set to suit the most arduous conditions.

Downloads

Submersible Pump Brochure (PDF 2MB)

Submersible Pump Specifications (PDF 0.4MB)

Submersible Pump Features (PDF 0.4MB)

Sizes: 4" - 12" bowls

Max Capacities: 573m3/hr (higher flows available on request)

Max Static Flow Temp: 55°C

Max Head: 400m

Speeds: 50Hz and 60Hz available

HEAD OFFICE

Flowdirect UK Ltd

Warmco Industrial Park

East Gate, Manchester Road

Mossley

OL5 9AY

T +44 (0)1484 637 970